Custom Cemented Tungsten Carbide Alloy Cylindrical Thin Walled Casing Seal Sleeve Bushing Liner for PDC Drilling Oil Equipment

Product Description

Product Parameters

| Grade | Composition (% in weight) | Physical Properties | Grain size (μm) |

|---|

| WC | Ni | Ti | TaC | Density g/cm³ (±0.1) | Hardness HRA (±0.5) | TRS Mpa (min) | Porosity A/B/C |

|

|---|

| KD115/YG6X | 93.5 | 6.0 | - | 0.5 | 14.90 | 93.0 | 2700 | A02/B00/C00 | 0.6-0.8 |

| KD335/YG10X | 89.0 | 10.5 | - | 0.5 | 14.40 | 91.8 | 3800 | A02/B00/C00 | 0.6-0.8 |

| KG6/YG6 | 94.0 | 6.0 | - | - | 14.90 | 90.5 | 2500 | A02/B00/C00 | 1.2-1.6 |

| KG8/YG8 | 92.0 | 8.0 | - | - | 14.75 | 90.0 | 3200 | A02/B00/C00 | 1.2-1.6 |

| KG9/YG9 | 91.0 | 9.0 | - | - | 14.60 | 89.0 | 3200 | A02/B00/C00 | 1.2-1.6 |

| KG9C/YG9C | 91.0 | 9.0 | - | - | 14.60 | 88.0 | 3200 | A02/B00/C00 | 1.6-2.4 |

| KG10/KG10 | 90.0 | 10.0 | - | - | 14.50 | 88.5 | 3200 | A02/B00/C00 | 1.2-1.6 |

| KG11/YG11 | 89.0 | 11.0 | - | - | 14.35 | 89.0 | 3200 | A02/B00/C00 | 1.2-1.6 |

| KG11C/YG11C | 89.0 | 11.0 | - | - | 14.40 | 87.5 | 3000 | A02/B00/C00 | 1.6-2.4 |

| KG13/YG13 | 87.0 | 13.0 | - | - | 14.20 | 88.7 | 3500 | A02/B00/C00 | 1.2-1.6 |

| KG13C/YG13C | 87.0 | 13.0 | - | - | 14.10 | 87.0 | 3500 | A02/B00/C00 | 1.6-2.4 |

| KG15/YG15 | 85.0 | 15.0 | - | - | 14.00 | 87.5 | 3500 | A02/B00/C00 | 1.2-1.6 |

| KG15C/YG15C | 85.0 | 15.0 | - | - | 14.50 | 86.5 | 3500 | A02/B00/C00 | 1.6-2.4 |

| KD118/YG8X | 91.5 | 8.5 | - | - | 14.10 | 93.6 | 3800 | A02/B00/C00 | 0.4-0.6 |

| KD338/YG12X | 88.0 | 12.0 | - | - | 12.60 | 92.8 | 2200 | A02/B00/C00 | 0.4-0.6 |

| KD25/P25 | 77.4 | 8.5 | 6.5 | 6.0 | 12.70 | 91.8 | 2200 | A02/B00/C00 | 1.0-1.6 |

| KD35/P35 | 69.2 | 10.5 | 5.2 | 13.8 | 13.25 | 91.1 | 2500 | A02/B00/C00 | 1.0-1.6 |

| KD10/M10 | 83.4 | 7.0 | 4.5 | 4.0 | 12.33 | 93.0 | 2000 | A02/B00/C00 | 0.8-1.2 |

| KD20/M20 | 79.0 | 8.0 | 7.4 | 3.8 | 12.33 | 92.1 | 2200 | A02/B00/C00 | 0.8-1.2 |

NOTE: Customization available per customer drawing or actual sample

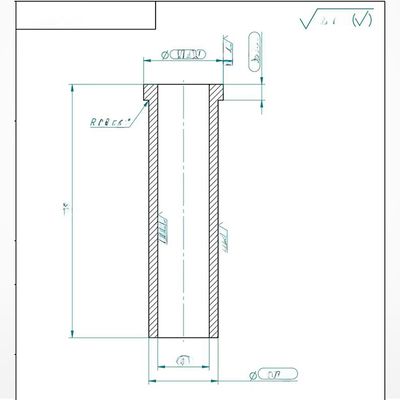

| Specification | OD (D:mm) | ID (D1:mm) | Pore (d:mm) | Length (L;mm) | Step length (L1:mm) |

|---|

| 01 | 16.41 | 14.05 | 12.70 | 25.40 | 1.00 |

| 02 | 16.41 | 14.05 | 12.70 | 31.75 | 1.00 |

| 03 | 22.04 | 18.86 | 15.75 | 31.75 | 3.18 |

| 04 | 22.04 | 18.86 | 15.75 | 50.80 | 3.18 |

| 05 | 16.00 | 13.90 | 10.31 | 76.20 | 3.18 |

| 06 | 22.00 | 18.88 | 14.30 | 25.40 | 3.18 |

| 07 | 24.00 | 21.00 | 16.00 | 75.00 | 3.00 |

| 08 | 22.90 | 21.00 | 15.00 | 75.00 | 3.00 |

| 09 | 19.50 | 16.90 | 12.70 | 50.00 | 4.00 |

| 10 | 36.80 | 32.80 | 26.00 | 55.00 | 4.00 |

Details Images

Why Choose Us

Company Profile

Exhibition

Frequently Asked Questions

How to obtain an accurate quotation from Kedel Tools?

Please provide us with specific material requirements, precise dimensions, and drawings that include tolerances and quantities for different models. This will allow us to provide you with a more accurate quote.

How does our company ensure the quality of its products?

We have inspection processes from raw material production, to finished product grinding, to cleaning and packaging. Each process also has sampling inspection. If the product in the previous process is not qualified, it will never enter the second process. Ensure the quality of the finished product.

How long does a typical production cycle take?

For products that are often in stock, they can be shipped directly. For customized products, the specific judgment is based on the difficulty level of product processing. Normally, non-standard products require 20-25 days for production.

What is our company's payment method?

We accept wire transfers, L/C, ALIPAY, WEST UNION, PAYPAL, 100% payment is required for standard products before shipment, 50% for non-standard products before production, and 50% before shipment.

In our journey at Kedel Technology Co., Ltd. in Chengdu, every encounter with you is our honor. We are well aware that being able to stop here among the many choices is our greatest support and recognition. Your satisfaction is our relentless pursuit, and every positive review and repurchase is the driving force that inspires us to keep moving forward.

Xếp hạng tổng thể

Hình chụp xếp hạng

Sau đây là phân phối của tất cả các xếp hạngTất cả các đánh giá